Transforming

Satellite Propulsion

With Stunning Simplicity

We’re pushing the boundaries of what’s possible for the near-earth economy through innovation and imagination.

Enpulsion is expanding satellite mobility and maneuverability. Drawing on our deep industrial expertise and proven in-flight heritage, we provide simple, reliable technology that meets our customers' evolving needs.

280+

Propulsion Systems in Space

420

Cumulative Years On-Orbit

As we help our customers accomplish their near-earth objectives, we leverage practical insights and information from every mission to drive innovation and fuel success.

Explore the propulsion lineup.

Mobility Suite

A full mobility suite designed for simple control & seamless performance

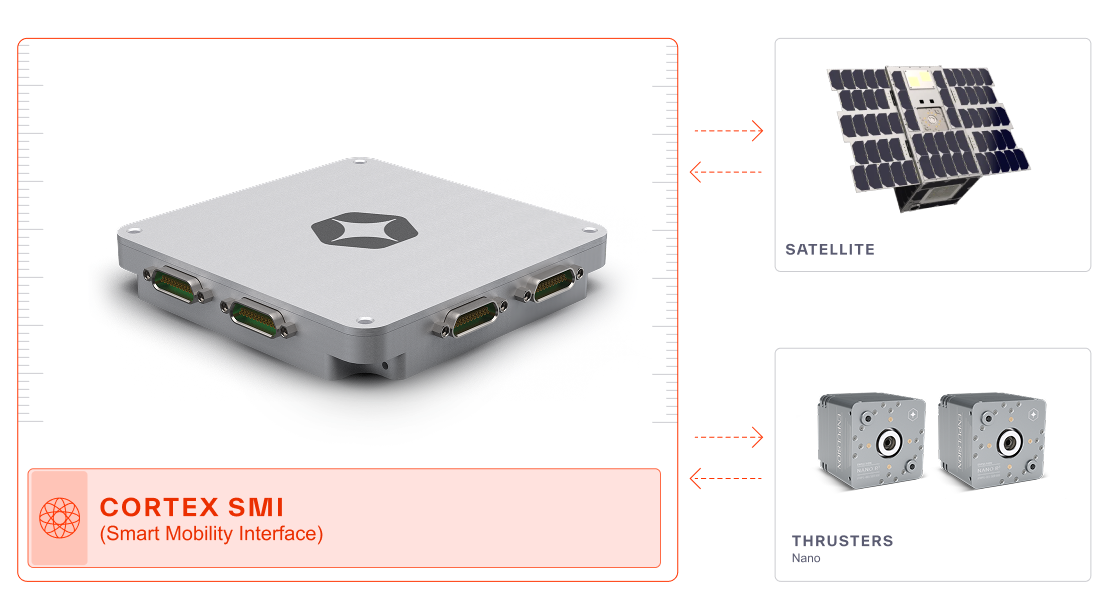

Cortex Smart Mobility Interface

Customize multiple interfaces. Control multiple thrusters. All from a single platform.

The Cortex Smart Mobility Interface (SMI) is a product interface designed to enable customers to control multiple thrusters via a common interface instead of directly interacting with the thrusters.

Each Cortex SMI operates with pre-defined protocols for Enpulsion thrusters, providing an enhanced interface with your platform and expanding the number of possible customizations and constellation options.

- Compliant with CubeSat standards V14 Rev2

- DC/DC Converters Nano (12V)

- Includes internal script support for thrust maneuvering

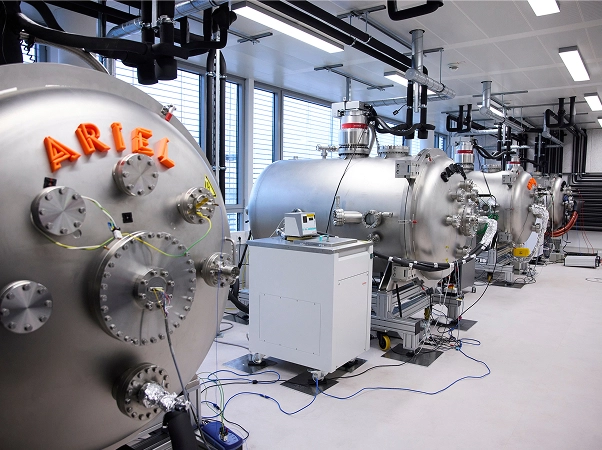

Industrial Capabilities

Combining high-performance technology with high-rate production capabilities, Enpulsion is perfectly positioned to scale based on your constellation objectives.

Our product lifecycle philosophy combines proven quality processes with a lean manufacturing methodology, enabling us to deliver exceptional product performance, consistent cost reduction, and short cycle times.

ISO 9001:2015 Certification

Certified Quality

Obtained in 2019, this certification underscores Enpulsion’s commitment to quality without compromises and constant improvement of products and processes.

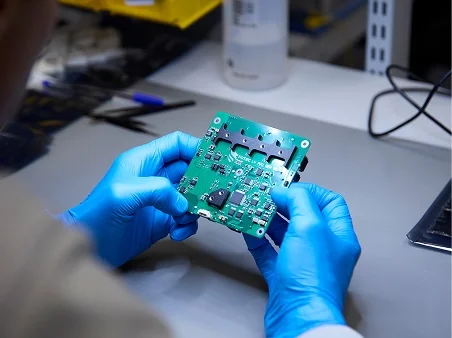

Inspection of Every Mechanical Part

Material Inspection

Understanding that every detail is important, we start by verifying the quality of every component used in our designs.

100% Traceability Manufacturing & Testing

Part Traceability

We build trust with every customer by operating with complete transparency and accountability in every aspect of our business.

Lean Production, High Throughput

Kanban Production

Using the Kanban production system, we optimize manufacturing workflows, reduce waste, and maximize our production efficiency.

Batch Testing on Part, Component & System Level

Batch Testing

By assessing the quality of our propulsion solutions at every level, we ensure simple operation and reliable performance from mission launch to final deorbiting.

100% Functional Acceptance Testing

Acceptance Testing

Understanding the mission-critical role of our solutions, we test every unit to ensure it meets or exceeds the highest performance and reliability standards.