Expert Insights & Support To Ensure Mission Success

Every system we design, service we provide, and decision we make is focused on maximizing reliability, streamlining operations, and enabling optimal performance throughout your mission lifecycle.

280+

Propulsion Systems in Space

420

Cumulative Years On-Orbit

Enpulsion's propulsion systems have a proven history of powering diverse missions with cutting-edge satellite mobility.

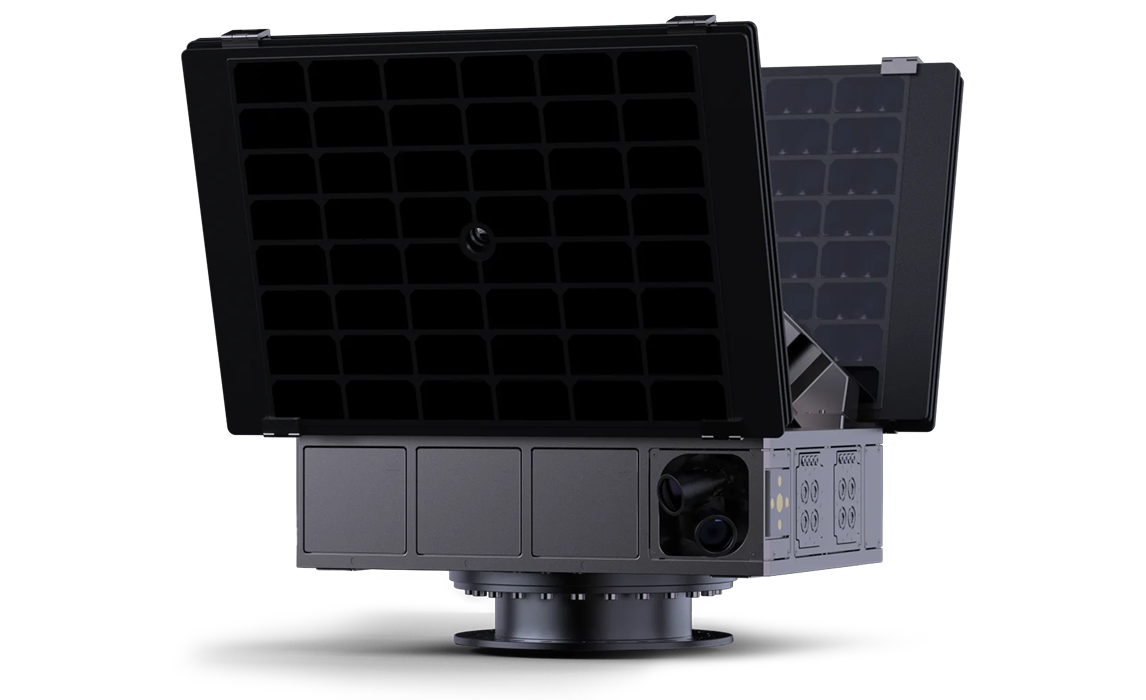

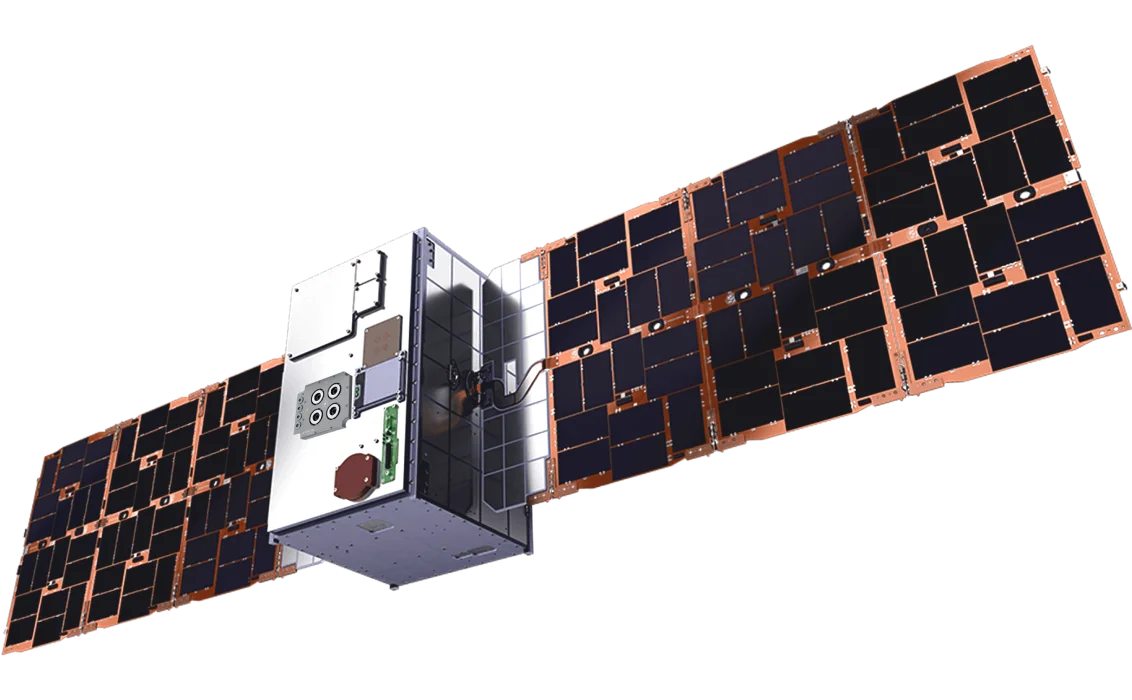

*Image courtesy of EnduroSat

Industrial Capabilities

Integrating high-performance engineering with scalable, high-throughput production, Enpulsion creates innovative mobility solutions to meet the evolving demands of your satellite missions and constellation initiatives.

Our product lifecycle strategy combines rigorous quality systems with lean manufacturing principles to deliver exceptional performance, reduced cost, and accelerated turnaround at every phase.

ISO 9001:2015 Certification

Certified Quality

Obtained in 2019, this certification underscores Enpulsion’s commitment to quality without compromises and constant improvement of products and processes.

Inspection of Every Mechanical Part

Material Inspection

Understanding that every detail is important, we start by verifying the quality of every component used in our designs.

100% Traceability Manufacturing & Testing

Part Traceability

We build trust with every customer by operating with complete transparency and accountability in every aspect of our business.

Lean Production, High Throughput

Kanban Production

Using the Kanban production system, we optimize manufacturing workflows, reduce waste, and maximize our production efficiency.

Batch Testing on Part, Component & System Level

Batch Testing

By assessing the quality of our propulsion solutions at every level, we ensure simple operation and reliable performance from mission launch to final deorbiting.

100% Functional Acceptance Testing

Acceptance Testing

Understanding the mission-critical role of our solutions, we test every unit to ensure it meets or exceeds the highest performance and reliability standards.

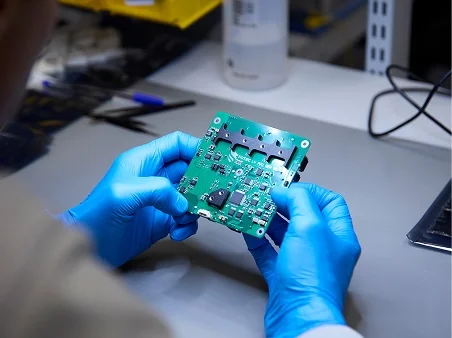

Quality and Precision

We refine every detail to ensure extraordinary quality at every stage

Incoming Inspection

Our automated incoming inspection streamlines the design throughput, ensuring industry-leading quality with 100% part verification. Fast issue reporting links directly to suppliers, keeping everything compliant, efficient, and launch-ready.

Emitter Production

The core component of Enpulsion’s IFM technology, our emitters are precision-crafted from incoming parts. Advanced parallel batch manufacturing with synchronized inspections ensures efficiency, consistency, and seamless production flow.

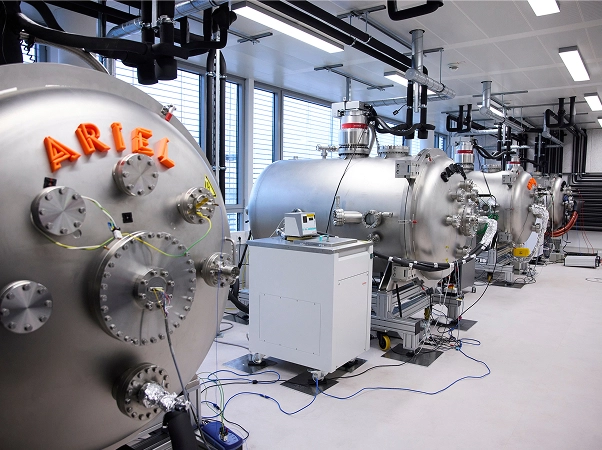

Propellant Loading

Next, we load each emitter with propellant, following the same high-efficiency scaling approach, using a precise vacuum process to ensure optimal performance while maintaining seamless production flow.

Emitter Characterization

In this step, semi-finished emitters undergo an initial characterization in vacuum facilities. We use batch testing and automated scripts to streamline the process, reducing chamber evacuation times and maximizing efficiency.

Scanning & Pre-Selection

We use advanced topology scanning to characterize emitters, leveraging predictive statistical models that optimize selection and quickly identify emitters that fall short of our rigorous performance standards.

Final Assembly

Selected emitters and preassembled components are stored, ready for final thruster assembly. Customer-driven configuration kicks off a rapid, Kanban-based process, which produces fully assembled thrusters in just hours.

Thermal Acceptance Testing

After final assembly, thrusters undergo rigorous acceptance testing, which incorporates mission-specific conditions provided by the customer. Batch testing ensures efficiency without compromising timelines or precision.

Vibration Testing

Assembled thrusters undergo vibration testing, conducted in parallel with thermal acceptance testing to maximize efficiency while ensuring they meet our established performance standards.

Functional Acceptance

Thrusters undergo final functional firing tests in vacuum facilities, with digitalized reporting and agile workflows ensuring swift decisions and rapid replacement for major non-conformances.

Final Inspection & Shipping

Final inspection, packaging, and shipping follow a streamlined, flexible process optimized based on customer input. Close collaboration with our logistics partners enables fast turnaround and timely delivery.

Mission Support

Enpulsion supports you at every stage of your mission

Engineering Support

Enpulsion provides end-to-end support, from product integration to in-orbit performance.

Our experts assist with assembly, troubleshooting, and mission execution, offering on-ground help and optional service packages. Whether during launch prep or in orbit, we ensure your propulsion system performs exactly as designed.

- On-Ground Support

- On-Orbit Support

FEEP Workshop

The FEEP Workshop empowers your team with more than knowledge. It delivers confidence, hands-on insight, and a mission-ready mindset.

The agenda features live tests in a compact vacuum chamber, which can be tailored to your mission needs. This ensures your team gains a clear, operational understanding of our technology, systems, and solutions.

To provide the most beneficial experience, the typical three-day workshop agenda includes:

- Intro to FEEP physics & manual theory

- Propulsion system operation using Enpulsion GUI

- Propulsion system operation with customer-provided equipment

- Customization of commissioning strategy

Explore the propulsion lineup.

Frequently asked questions

Talk to an Expert

Learn how our experts can help guide your implementation

Matthew Randall

Global Director of Business Development and Sales

Coming Soon

Enpulsion Simulator Suite

Our Thruster Simulator Suite uses cutting-edge software to enable end-to-end thruster and satellite testing across all mission phases.

Be one of the first to explore our next-gen Simulator Suite — sign up to get notified when it goes live.