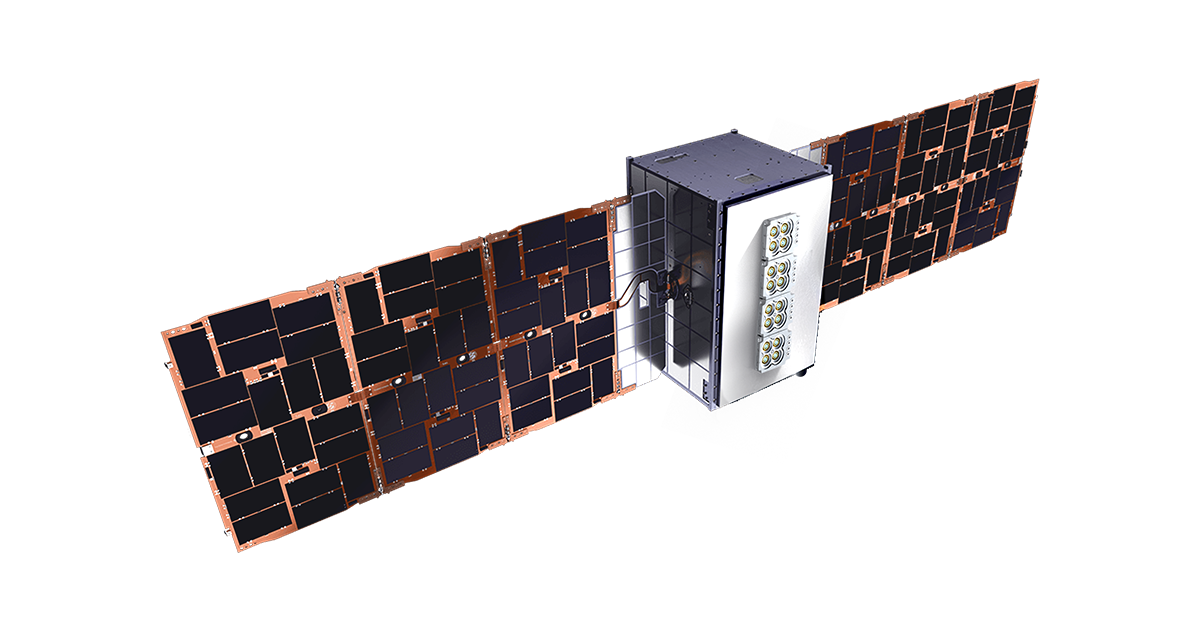

Orbit raise and deorbit for SDA-class buses

(150—500 kg)

For small satellites requiring next-gen propulsion, Nexus offers higher thrust, greater agility, and seamless integration.

Built on the proven TRL 9 and MRL 9 heritage of our Micro R3, this breakthrough innovation delivers a superior thrust-to-power ratio while maintaining Enpulsion’s hallmark simplicity and reliability. Ideal for constellations, responsive missions, and advanced maneuvering or deorbit operations, Nexus brings powerful mobility to critical missions.

Single(1) |

Dual(2) |

Triple(3) |

Quad(4) |

|

|---|---|---|---|---|

| Dynamic Thrust Range | 700 µN – 1.72 mN Need more thrust? | 700 µN - 3.5mN | 700 µN - 5.28 mN | 700 µN - 7.06mN |

| Specific Impulse | 500 – 4,500 Seconds | 500 – 4,500 Seconds | 500 – 4,500 Seconds | 500 – 4,500 Seconds |

| Propellant Mass | 1.3 kg Indium | 2.6 kg Indium | 3.9 kg Indium | 5.2 kg Indium |

| Total Impulse | Up to 30,000 Ns (30 kNs) | Up to 60,000 Ns (60 kNs) | Up to 90,000 Ns (90 kNs) | Up to 120,000 Ns (120 kNs) |

| Outside Dimensions | Thruster head: 140 x 120 x 160 mm | |||

| Mass (Dry/Wet) | 3.6 kg / 4.9 kg | 7.2 kg / 9.8 kg | 10.8 kg / 14.7 kg | 14.4 kg / 19.6 kg |

| Hot Standby Power | 15 - 25 W | 30 – 40 W | 40 – 50 W | 55 – 65 W |

| Total System Power | 50 – 150 W Need more power? | 70 – 300 W | 90 – 450 W | 120 – 600 W |

| Command Interface | RS422 / RS485 | RS422 / RS485 | RS422 / RS485 | RS422 / RS485 |

| Thruster Head Dimensions | (140 x 120 x 160 mm) | (140 x 120 x 160 mm) x 2 | (140 x 120 x 160 mm) x 3 | (140 x 120 x 160 mm) x 4 |

| Download Data Sheet | Download Data Sheet | Download Data Sheet | Download Data Sheet |

Flight-Proven Foundation

Built on the in-orbit success of over 280 flight-proven propulsion systems, Nexus Osprey leverages years of insights gained through production experience across diverse mission profiles.

Built-In System Resilience

With approximately 480 ion emission sites and parallel high-voltage supplies, Nexus Osprey design offers exceptional resilience and system-level robustness.

Compact Performance Boost

Delivering up to 4500s specific impulse with a propellant four times denser than xenon, Nexus Osprey packs high performance into a compact architecture.

Optimized Thrust Efficiency

Optimized for power and performance, Nexus Osprey increases thrust-to-power efficiency over lower-power systems by intelligently scaling beam output.

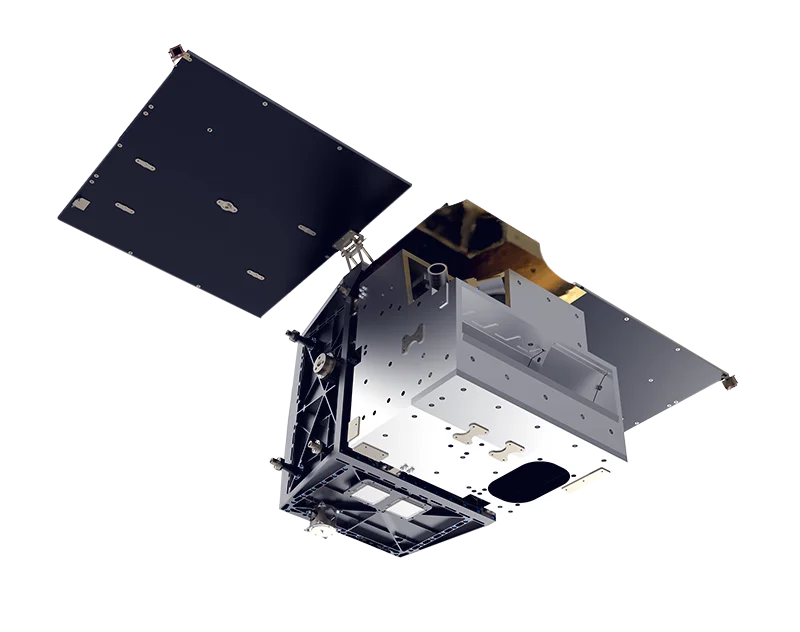

Plug-and-Play Design

Thanks to its design without tanks or fluidic systems, Nexus Osprey installs via standard mounting panels and harnessing, connecting within a 15-inch ESPA-class ring.

Inherent Operational Safety

With no pressurized tanks or stored chemical energy, the system eliminates explosive risk during active operation or in-orbit collisions, enhancing overall spacecraft safety.

Stable, Safe Fuel Source

Indium is a nontoxic, unpressurized metal sourced as a by-product of zinc refining. More than 1,000 tons are produced annually, offering a stable, accessible, and safe propellant option.

With a clearly defined launch plan, Nexus is positioned to support confident mission planning and early engagement. The timeline below highlights key milestones in development, qualification, and delivery.

(150—500 kg)

(e.g., SDA, MDA, tech demos)

(using secondary thrusters)

Indium propellant liquifies in orbit to generate finely tunable thrust, delivering efficient, precise maneuverability throughout the entire life of the mission.

György Biró

Global Director of Strategic Business Development and Sales

Our Thruster Simulator Suite uses cutting-edge software to enable end-to-end thruster and satellite testing across all mission phases.

Be one of the first to explore our next-gen Simulator Suite — sign up to get notified when it goes live.