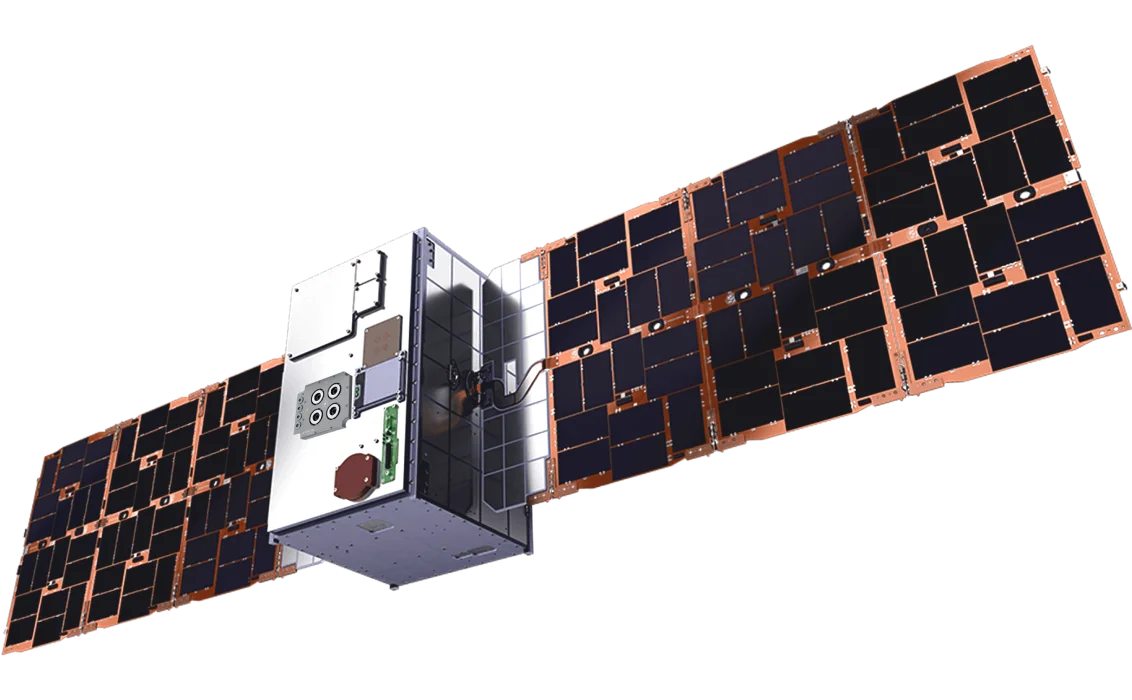

Pushing satellite propulsion to the next level

Enpulsion thrusters enhance mission success through cutting-edge technology, innovative design, and scalable manufacturing.

Explore the propulsion lineup.

Micro StarlingThe Micro Starling is a scaled version of our flight-proven thruster design, making it the ideal propulsion system for small and medium-sized spacecraft. |

Nano LarkThe Nano Lark packs the power and precision FEEP technology in a compact design, delivering superior reliability, radiation tolerance, and environmental resilience. |

Single(1)The most powerful FEEP system ever, the Nexus delivers the performance benefits of FEEP propulsion for medium-sized spacecraft that traditionally rely on complex Hall effect thrusters. |

|

|---|---|---|---|

| Dynamic Thrust Range | 300 µN - 1 mN Need more thrust? | 50 TO 350 µN Need more thrust? | 700 µN – 1.72 mN Need more thrust? |

| Nominal Thrust | 1 mN |

350 µN |

|

| Specific Impulse | 1,500 - 4,500 s |

1,500 TO 4,500 s |

500 – 4,500 Seconds |

| Propellant Mass | 1.3 kg |

220 g |

1.3 kg Indium |

| Total Impulse | Up to 50 kNs |

More than 4,000 Ns |

Up to 30,000 Ns (30 kNs) |

| Outside Dimensions |

Thruster head: 140 x 120 x 98.6 mm | PPU box: 140 x 120 x 34.0 mm |

98.0 x 99.0 x 95.3 mm | Thruster head: 140 x 120 x 160 mm |

| Mass (Dry/Wet) | 2.6 kg / 3.9 kg | <1280 / <1500 g | 3.6 kg / 4.9 kg |

| Hot Standby Power | 10 - 15 W | 4 - 7 W | 15 - 25 W |

| Total System Power | 30 - 120 W Need more power? | 15 – 45 W Need more power? | 50 – 150 W Need more power? |

| Command Interface | RS422 / RS485 | RS422 / RS485 | RS422 / RS485 |

| Supply Voltage | 12 V | ||

| Thruster Head Dimensions | (140 x 120 x 160 mm) | ||

| Data Sheet Download | Download Data Sheet | Download Data Sheet | Download Data Sheet |

Quality and Precision

We refine every detail to ensure extraordinary quality at every stage

Incoming Inspection

Our automated incoming inspection streamlines the design throughput, ensuring industry-leading quality with 100% part verification. Fast issue reporting links directly to suppliers, keeping everything compliant, efficient, and launch-ready.

Emitter Production

The core component of Enpulsion’s IFM technology, our emitters are precision-crafted from incoming parts. Advanced parallel batch manufacturing with synchronized inspections ensures efficiency, consistency, and seamless production flow.

Propellant Loading

Next, we load each emitter with propellant, following the same high-efficiency scaling approach, using a precise vacuum process to ensure optimal performance while maintaining seamless production flow.

Emitter Characterization

In this step, semi-finished emitters undergo an initial characterization in vacuum facilities. We use batch testing and automated scripts to streamline the process, reducing chamber evacuation times and maximizing efficiency.

Scanning & Pre-Selection

We use advanced topology scanning to characterize emitters, leveraging predictive statistical models that optimize selection and quickly identify emitters that fall short of our rigorous performance standards.

Final Assembly

Selected emitters and preassembled components are stored, ready for final thruster assembly. Customer-driven configuration kicks off a rapid, Kanban-based process, which produces fully assembled thrusters in just hours.

Thermal Acceptance Testing

After final assembly, thrusters undergo rigorous acceptance testing, which incorporates mission-specific conditions provided by the customer. Batch testing ensures efficiency without compromising timelines or precision.

Vibration Testing

Assembled thrusters undergo vibration testing, conducted in parallel with thermal acceptance testing to maximize efficiency while ensuring they meet our established performance standards.

Functional Acceptance

Thrusters undergo final functional firing tests in vacuum facilities, with digitalized reporting and agile workflows ensuring swift decisions and rapid replacement for major non-conformances.

Final Inspection & Shipping

Final inspection, packaging, and shipping follow a streamlined, flexible process optimized based on customer input. Close collaboration with our logistics partners enables fast turnaround and timely delivery.

Industrial Capabilities

Our propulsion technology delivers dynamic thrust control and adaptable specific impulse — expanding the possibilities of satellite mobility through expert innovation.

Indium-Powered Propulsion

Safe, Compact Metal Propellant

An inert metal propellant produced at an industrial scale, Indium is compact, safe, and pre-filled for easy deployment. No special authorizations, pressurized tanks, or costly fueling required.

Learn More

Customizable Configurations

Modular Construction

Modular construction and self-contained propulsion systems make it easy to create custom mobility solutions that are cost-effective and built with minimal lead times.

Resilient, Reliable Design

Backed by Heritage

Built on the flight heritage of our legacy thrusters, our latest models are designed to deliver superior radiation protection and enhanced electric reliability for the entire mission.

Custom Designed for Mission Success

Learn how FEEP technology transforms propulsion with precision

Talk to an Expert

Talk to an expert about our full-scale mobility suite

Matthew Randall

Global Director of Business Development and Sales